Another reason that the loss of hot boiler water is serious is because it increases the humidity in the boiler room and will contribute to the malfunction and failure of electrical controls safety devices and other electrical equipment.

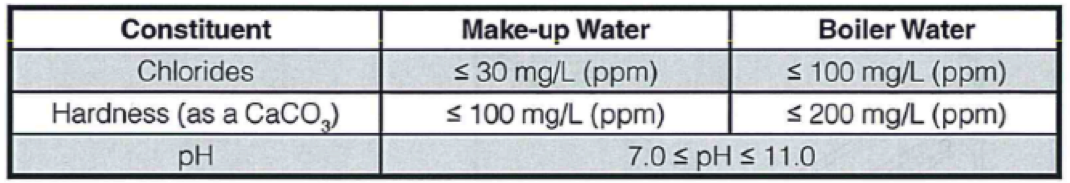

Steam boiler water hardness.

Non volatile toc total organic carbon oily matter.

Feed water purity requirements therefore can vary widely.

However boiler water is deliberately softened to prevent scale formation and this gives it a propensity to foam.

For boiler water the conductivity increases at the rate of approximately 2 of the value at 25 c for every 1 c increase in temperature.

In order for this reaction to take place it is important to maintain a ph at a minimum value of 9 50.

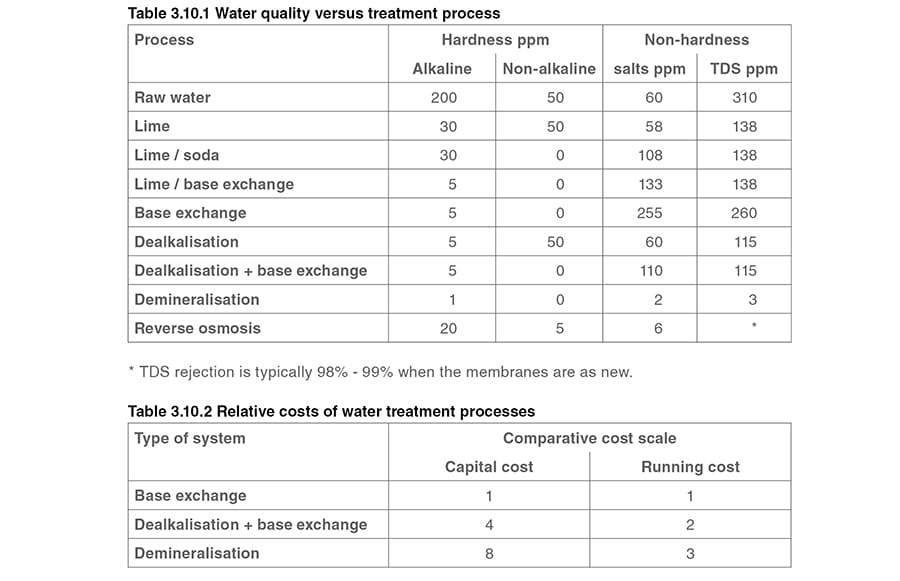

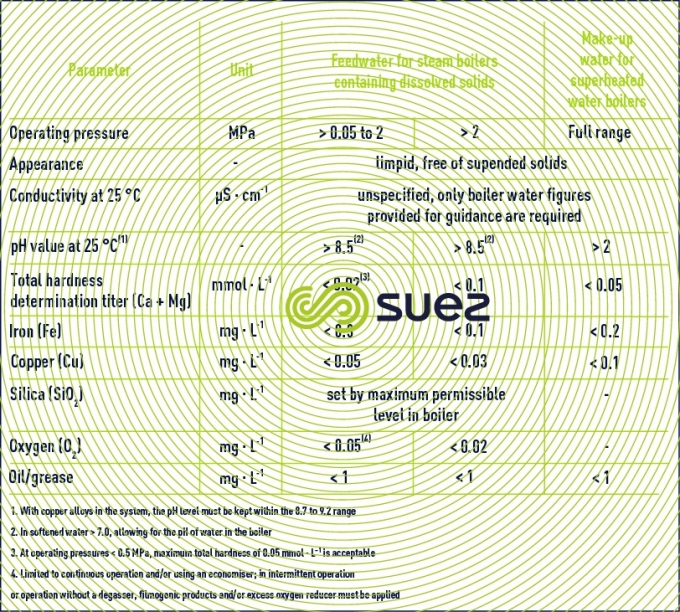

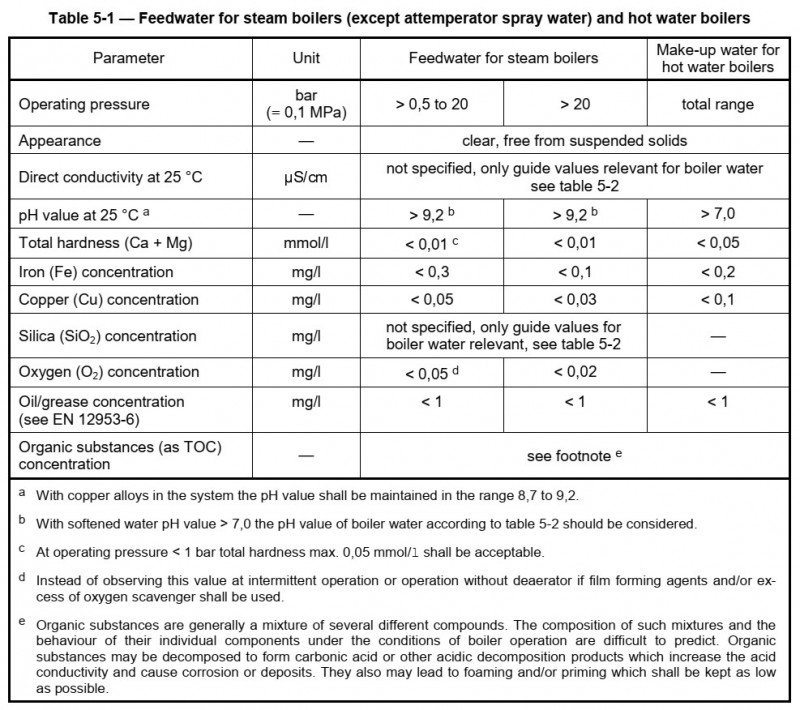

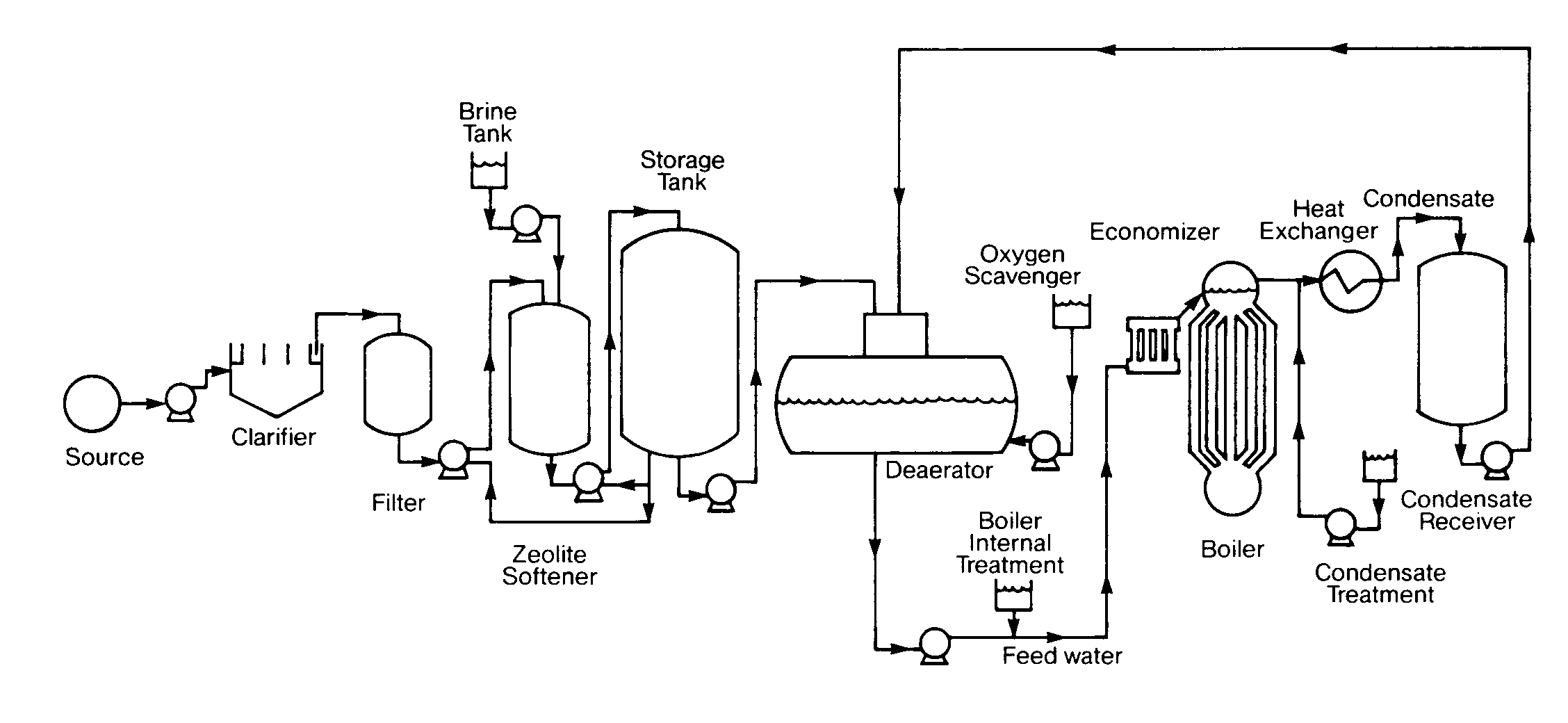

Water treatment recommendations vary depending on the operating pressure of the boiler the application steam or hot water and other parameters.

A low pressure fire tube boiler can usually tolerate high feed water hardness with proper treatment while virtually all impurities must be removed from water used in some modern high pressure boilers.

Total silica 150 ppm maximum.

It is desirable to keep the concentration of phosphates in the water to 30 50 ppm in order for complete reaction of the phosphates with the calcium hardness entering the.

Total hardness 1 ppm maximum.

Hardness hard water does not foam.

This value will limit the silica content of the steam to 0 25 ppm as a function of selective.

Phosphates are used to react with calcium hardness in the boiler water.

Broken down by feed water and boiler water and then by firetube.

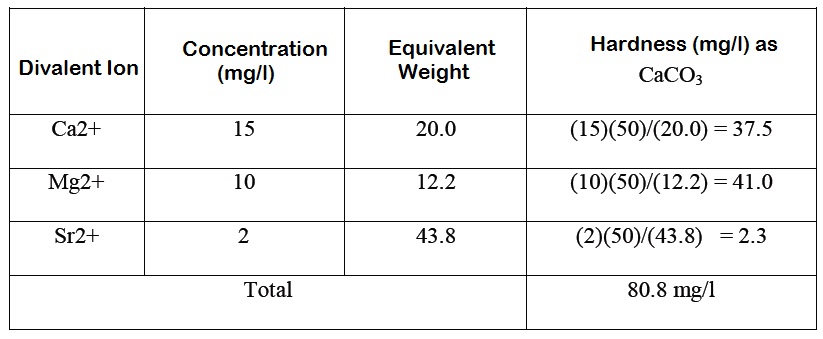

The concentration of minerals in the water is referred to as the water hardness.

Colloidal substances contamination of boiler water with a colloid in suspension for example.

General guidelines to prevent corrosion and scaling in low pressure boilers are as follows.

Total alkalinity 600 ppm maximum.

Feed water boiler water characteristics as per is 10392 1982 1 feed water parameters upto 20 kg cm2 21 kg cm2 to 39 kg cm2 40 kg cm2 to 59 kg cm2 unit total hardness 10 1 0 0 5 ppm as caco 3 ph value 8 5 9 5 8 5 9 5 8 5 9 5 dissolved oxygen.

Colloidal particles are less than 0 000 1 mm in diameter and.

An increase in temperature results in an increase in electrical conductivity.

Milk causes violent foaming.

This can be written as.

Colormetry hardness detector prevent water hardness damage to your boiler with miura s colormetry hardness detection system.

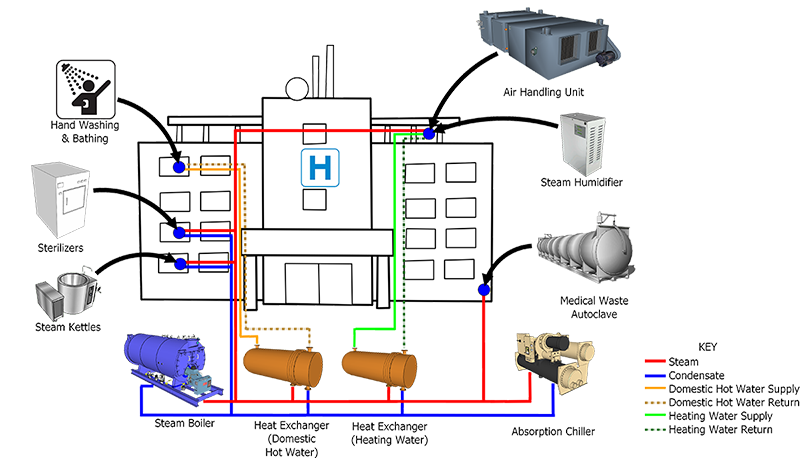

Most boiler systems have sodium zeolite softened or demineralized makeup water.

Water hardness levels are typically checked manually through the use of chemical reagents but such measurements are time consuming and can result in incorrect readings.